SpotlightLumos Maxima! Introducing IWC’s First Concept Watch Showcasing Ceralume Technology

IWC have developed their first fully luminous concept watch, featuring Ceralume—a proprietary ceramic technology, showcased in the one-off piece—the Pilot’s Watch Chronograph 41

May We Recommend

The watchmaking industry is no stranger to luminescent materials—a concept that revolutionised timekeeping by enhancing the functionality of watches back in the early 1900s when it was incorporated into timepieces, especially the ones made for marine professionals. While these initial experiments with luminescence were path-breaking, they weren’t the safest as back then, watchmakers used radium—a radioactive substance, which ultimately had to be discontinued. However, this led the way for watch brands to innovate and launch safer alternatives to continue on the ‘enlightened’ path.

Among them, IWC is a name to reckon with as the brand has mastered the art of developing watches that glow in the dark, especially in their Pilot’s collection. This is an integral element for their timepieces as it assists with legibility in low-light areas—an essential feature for aviation. And in their pursuit of creating luminous watches, IWC have taken it up a notch by introducing the Ceralume technology in the Pilot’s Watch Chronograph 41—a concept piece showcasing the brand’s expertise in engineering high-quality ceramic watches—strengthened over almost four decades. Back in 1986, they launched the world’s first timepiece with a black zirconium oxide ceramic case. Since then, the Swiss luxury watch brand has been innovating with this material to produce a range of timekeepers—including coloured ceramic. And with the Ceralume technology, they continue pushing the boundaries as this involves a ‘highly engineered and patent-pending manufacturing process’ developed by the brand.

“With the first fully luminous ceramic case rings, we underscore our role as a pioneer and innovator in ceramic watches. The development of Ceralume took several years. The main challenges we faced were producing watch cases with maximum homogeneity and meeting our exacting quality standards. To achieve these goals, we engineered a ground-breaking new manufacturing process—tailored to the unique combination of ceramic powders and Super-LumiNova pigments,” explains Dr Lorenz Brunner, Department Manager, Research & Innovation at IWC in the official press statement.

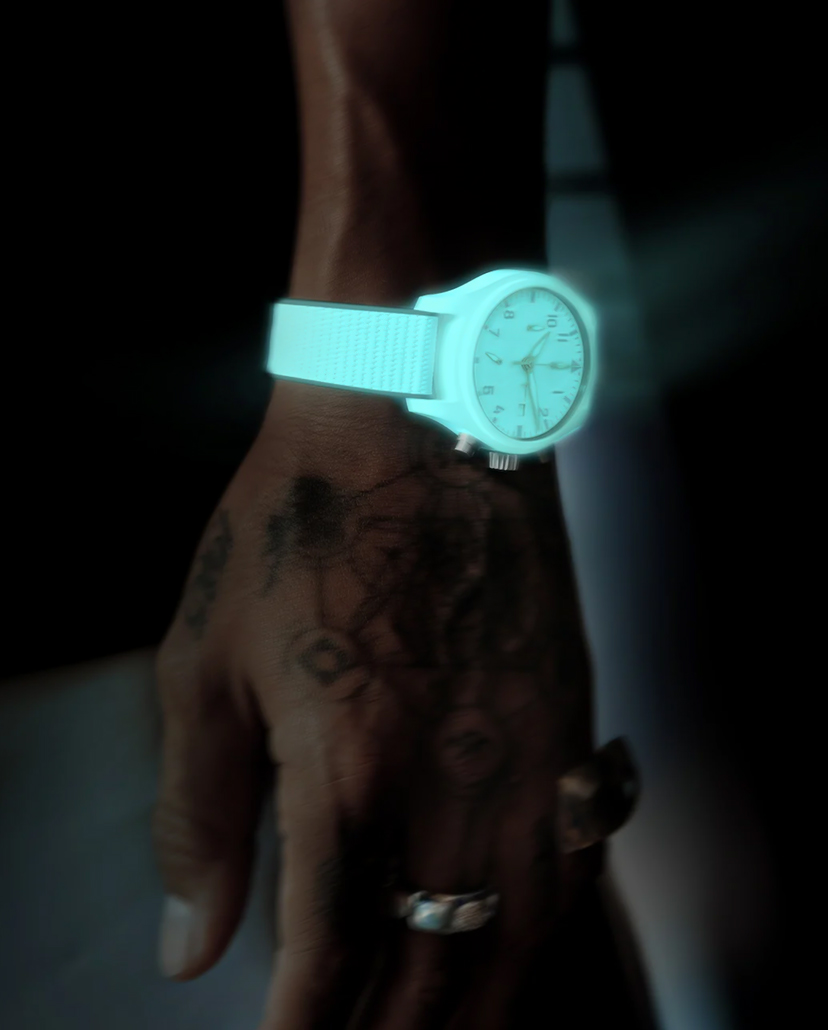

This concept watch with the Ceralume technology was recently debuted by Formula 1 ace driver and brand ambassador, Lewis Hamilton in Monaco, who was seen sporting the Pilot’s Watch Chronograph 41—glowing on his wrist. Here, in addition to its Ceralume case and the signature Pilot’s watch features, the concept watch showcases a white luminescent dial, presented on a white luminescent rubber strap. The dial’s brass base is sprayed with a Super-LumiNova solution before the printing is added on top of the luminescent layer. Manufactured in an injection moulding process, the white rubber strap is also enriched with Super-LumiNova pigments for that overall glow.

According to the brand, this effect is ‘achieved by adding high grade Super-LumiNova pigments to the ceramic raw materials’. Super-LumiNova behaves like a light storage battery since it absorbs light energy from sunlight or artificial light, and then emits this in low-light areas. The brand claims that ‘in dark chamber tests, Ceralume watch cases have emitted a bright blueish light for more than 24 hours’.

While conventional white ceramic is made by mixing zirconium oxide with other metallic oxides, Ceralume is made in a highly engineered process. One of the main challenges as stated in the brand literature ‘was achieving a perfectly homogeneous mix of raw materials despite their different particle sizes and avoiding particle accumulations. To achieve this, IWC’s engineers reverted to a dedicated ball milling process, which had to be customised to the raw materials used. In addition, the parameters of the sintering process and the grinding of the sintered ceramic body also needed to be specifically adapted to the luminous ceramic’.